If you’re in the market for new strapping tools or packaging equipment, you may be taking your time with the buying decision. After all, you hope the packaging equipment you purchase will last a long time. If these tools or machines are needed for years on end, you want to be sure you’re getting the best.

One of the decisions you’ll have to make will be whether to buy from a distributor or to purchase your equipment directly from the packaging manufacturer.

If this question is still on your list, then there are a few reasons you should be giving the packaging manufacturer higher marks. Here’s why you should choose a packaging manufacturer vs. distributor for your next packaging equipment purchase.

Packaging Manufacturer vs. Distributor Costs

The first reason for choosing the packaging manufacturer over the distributor is the cost of the equipment. The manufacturer will often be able to offer you a lower price for the same equipment.

Why? The distributor is buying the same equipment from the manufacturer too. The difference between your company and the distributor is that the distributor buys in bulk. That entitles them to a discount from the manufacturer, so they may be able to buy at a lower cost.

That’s not the price they’re charging you, though. The distributor will still mark up their discounted wholesale price. They want to make a profit, after all.

Depending on the distributor and the mark-up, that price may exceed the manufacturer’s own pricing. Going directly to the manufacturer might mean you’re able to swing your own deal as well, depending on how much you want to buy.

Get Better Product Support from the Manufacturer

What other reasons are there to consider a packaging manufacturer vs. distributor? One is the support and training you’ll receive.

Who would you rather hire to train your team: the people who made the equipment, or the people who bought the equipment off the people who made it?

The manufacturer knows their product inside-out, so they’re better positioned to provide the training your team needs. The right training goes a long way to keeping your employees safe and improving productivity in your plant.

The manufacturer is also in a better position to supply support. If your team is having an issue with a product, the distributor may get you to call the manufacturer or consult with the manufacturer themselves.

Finally, the manufacturer might be able to supply maintenance. They’ll certainly be better positioned to supply the right parts to keep your strapping tools and packing machines in working order. They may even provide a preventative maintenance program so you can keep your tools working even longer.

Customizing Your Solution with the Manufacturer

Another reason to consider packaging manufacturer vs. distributor is customization. The distributor is buying set solutions from the manufacturer. If your plant requires different specifications, the distributor may not be able to help you.

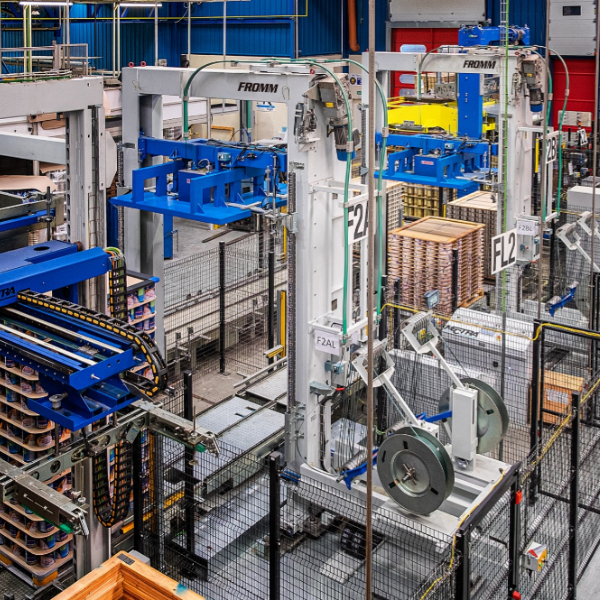

The wrong solution can drive down productivity and cause other headaches in your plant. When you work directly with the packaging manufacturer, you can customize your solution. Those headaches will disappear as you and the manufacturer design a solution that addresses the unique needs of your plant.

This is an important consideration for most plants. You might desire higher processing speeds, or need a solution that can strap awkward or bulky packages. No matter the challenge, a great solution is just a few steps away.

Get the Expert Knowledge You Need

Now you can see some of the advantages of working with a packaging manufacturer vs. distributor. Whether you need a handful of strapping tools or you’re looking for a fully automated, custom solution, the packaging manufacturer has your back.

Get in touch with the experts and discover the difference the right packaging solution can make for your plant.