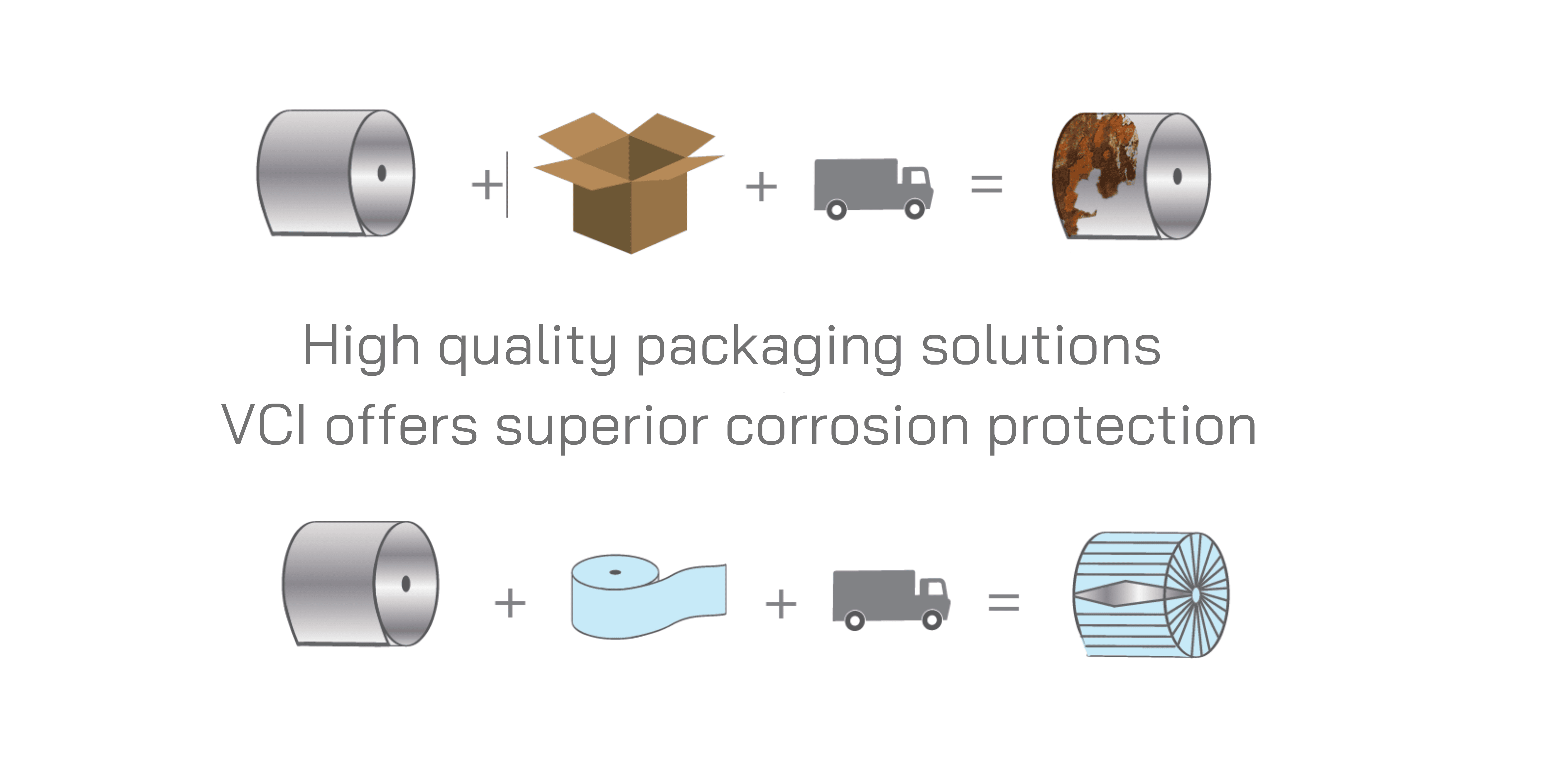

One concern any manufacturer has is making sure its product arrives in the customer’s warehouse undamaged. Most people think of physical damage, such as cracks or breaks. Depending on what you’re packing up and shipping out, though, there are many other types of damage that can occur.

Take, for example, metals with iron in them. Ferrous materials can experience corrosion, also known as metal oxidation, if they’re exposed to water and air. If you’re shipping automotive parts or other metal materials, you want to protect your product as best you can.

Even packaging can contribute to how much or how little corrosion happens during shipping and storage. That’s why VCI packaging was created. Although considered a breakthrough for its time, you now have better choices, such as BioCor.

What Is VCI Packaging?

VCI stands for volatile corrosion inhibitor. Some chemical compounds slow down or prevent the corrosion of metals such as iron and steel; they’re known as VCIs.

VCIs are used as additives to packaging materials, including paper and plastic. The presence of these chemicals protects the packaged items from corrosion. VCI packaging was common for automotive, steel, metal, and military packaging.

VCIs would be injected into the packaging material. When the film or paper is used, it emits molecules that settle on the metal surface to create a barrier that protects against corrosive agents. Even if a package were opened, the inhibitors would continue to protect what was inside after it was closed again.

Research Shows VCIs Are Dangerous

The earliest volatile corrosion inhibitors used nitrites, such as dicyclohexylammonium nitrite (DICHAN). Discovered in the 1940s, this substance was used to protect metal components in military vehicles. It soon made its way to other industries, including packaging.

Nitrites are considered dangerous, so substances such as DICHAN were banned. This led to more research to find better, safer VCIs, and other substances were introduced. Today, there is a second major group of VCIs, the amine-based VCIs. The amine group includes both secondary and tertiary amine VCIs.

Unfortunately, continued research has shown that neither nitrite-based nor amine-based VCIs are safe. These chemicals can combine and create nitrosamines, which are cancer-causing agents. When used in packaging, amines and nitrites form vapors that can then be inhaled.

As a result, many in the packaging industry are looking to move away from traditional VCIs. The need for alternatives has been heightened by bans on amine-based VCIs in countries such as Germany.

BioCor Is the Safer Choice

One of the emerging alternatives for those looking for safer packaging alternatives is BioCor., a plastic packaging material. This VCI film uses all-natural substances. There’s no need to synthesize dangerous chemicals such as nitrites and amines.

BioCor acts much like a traditional VCI, but it’s safer for your workers. It’s not toxic like older, nitrite- and amine-based VCIs.

With BioCor, you can protect both your product and your people. It’s available in several different formats, including bubble film, bags, and stretch wrap. Whether you need it to work with a stretch wrap machine to wrap pallets or you’re putting metal parts in bags, BioCor could be the right choice for your business.

Switch Your Packaging Today

If you’re still using amine- or nitrite-based VCI packaging, you could be putting yourself and others at risk. As shown, researchers have been hard at work developing other alternatives to older VCIs.

BioCor is one safer alternative, and you could start using it for your packaging today. If you’re ready to leave behind toxic chemicals and make your shipping department a safer place to be, get in touch with the experts. They can help you choose the right solution to protect both your product and your people.