You’ve decided to switch to polyester strapping. You’re concerned about the price of steel, as well as the safety and recyclability of it. Polyester strapping offers a much more flexible material that’s appropriate for all but the heaviest, non-compressible loads.

As you’re researching your options, you’re wondering about the different ways of creating closures for polyester straps. The strap is only as strong as its weakest link, after all, which is the point where it’s joined together.

So which method of closure should you be using when you use polyester?

Closing Polyester Strapping

You have three choices for closing polyester strapping. The first one is to use a metal closure. This can be a good choice for light-duty, low-volume packaging. With this method, the seal joint is usually less than half of the overall material’s strength. If you’re strapping a heavy load, that’s not good news.

Additionally, since you are dealing with a clip and two tools the process can be slow and time consuming when compared to other available methods.

However, as mentioned, for light-duty, low-volume applications, it may be the system of choice. It is the most economical of all because the tools are less expensive. However, seal costs can add up for higher volume usage.

This leaves two more effective methods for you to choose between. Both use thermal energy to create a seal.

The first is known as a friction joint weld, or friction welding. In this method, rapid vibration creates enough heat to fuse the two ends of the polyester strap together.

The other option you have is heat welding. This method uses a thermoelectric heater blade to melt the straps together under pressure.

Either of these two methods will create strong closures for your strapping.

The Type of Strapping Equipment You Use

The type of closure you use for your polyester strapping might depend on the type of equipment you have.

Friction welds are used by all hand strapping tools as well as most semi-automatic and automatic strapping machines. Friction welds have evolved to become the standard in the industry. However, there are still some machines being made with thermoelectric blades, but technology has started to limit their use.

For a variety of reasons thermoelectric blades are not feasible in portable battery operated equipment and all battery operated tools use friction welding.

The Type of Load You’re Strapping

Whether a friction weld or a heat weld is “better” could also depend on the method of application. Automatic machines work with loads such as lumber, fine paper, or cans and bottles.

In the past, it has been documented that environmental temperature can impact the quality of the heat weld. As temperature fluctuates in the surroundings, the thermoelectric plates have heat variances, which can cause abnormalities in the weld. Over time, the outer edges of heat plates sometimes become less effective in distributing heat evenly, causing weld defects.

No such problems exist in friction welding.

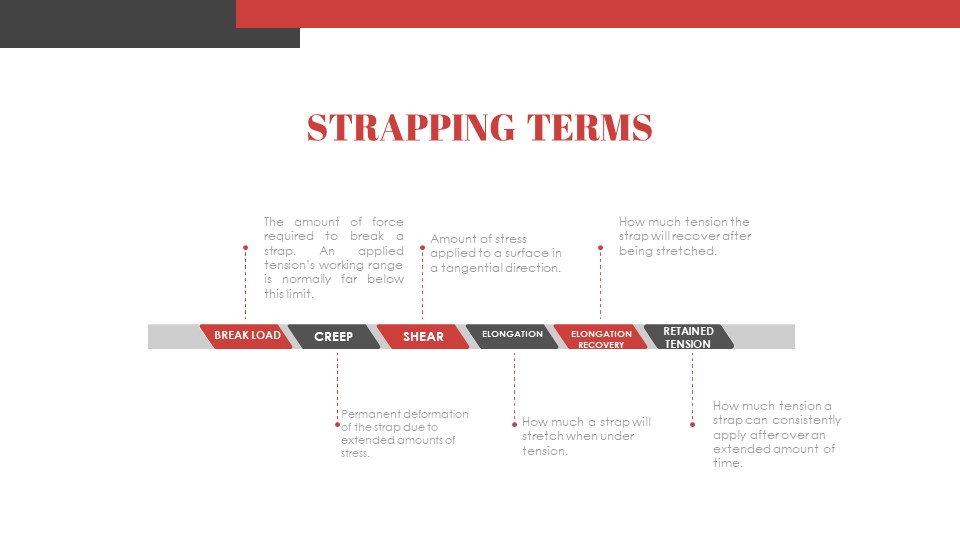

Considering Break Strength

Both friction joint welds and heat welding create relatively strong closures on the straps. Generally speaking, anything above 75 percent of the material’s break strength is considered an efficient seal joint.

Friction welding is often stronger, often exceeding the 75% percent of polyester strapping’s break strength.

The seal joint efficiency depends on a number of different factors, including the strapping material and the strapping machine used. The type of seal isn’t the only consideration, so be sure to consider all the factors. Without proper set up of the tool, no matter the technology used, strong welds will not be achieved.

Considering Costs

As noted, friction welding is the most common option with hand strapping tools. Heat welding is more common with automatic strapping machines, but friction welds still dominate

Seals are a good solution to keep initial cost low but should only be used in light-duty, low-volume applications. Pushing this limit on seals jeopardizes the integrity of the load, increases labour costs and ultimately the cost of seals eliminates any advantage of minimizing upfront tooling costs.

In this case, the “best” solution to weld polyester strapping may be the one that comes with the solution that fits your business’s needs.

So long as the material you’re using is appropriate for the loads you’re strapping, either a friction weld, heat weld, or seal could be the right choice. If you contact a local representative, they can further guide you through the process of choosing the right solution for your needs.