In 2026, warehouse automation isn't just a competitive advantage—it's survival. With labour shortages intensifying, sustainability mandates tightening, and autonomous mobile robots (AMRs) projected to dominate 60% of new automation deployments by year's end, the pressure to modernize your end-of-line operations has never been greater.

Yet while AI-powered picking robots and cloud-based WMS platforms grab headlines, there's an unsung hero quietly transforming warehouse efficiency: automated stretch wrapping.

Here's the reality: cutting corners on pallet wrapping usually means cutting into your profits. Unstable loads, climbing film costs, and chronic labour shortages aren't just operational headaches—they're profit killers that compound with every shipment.

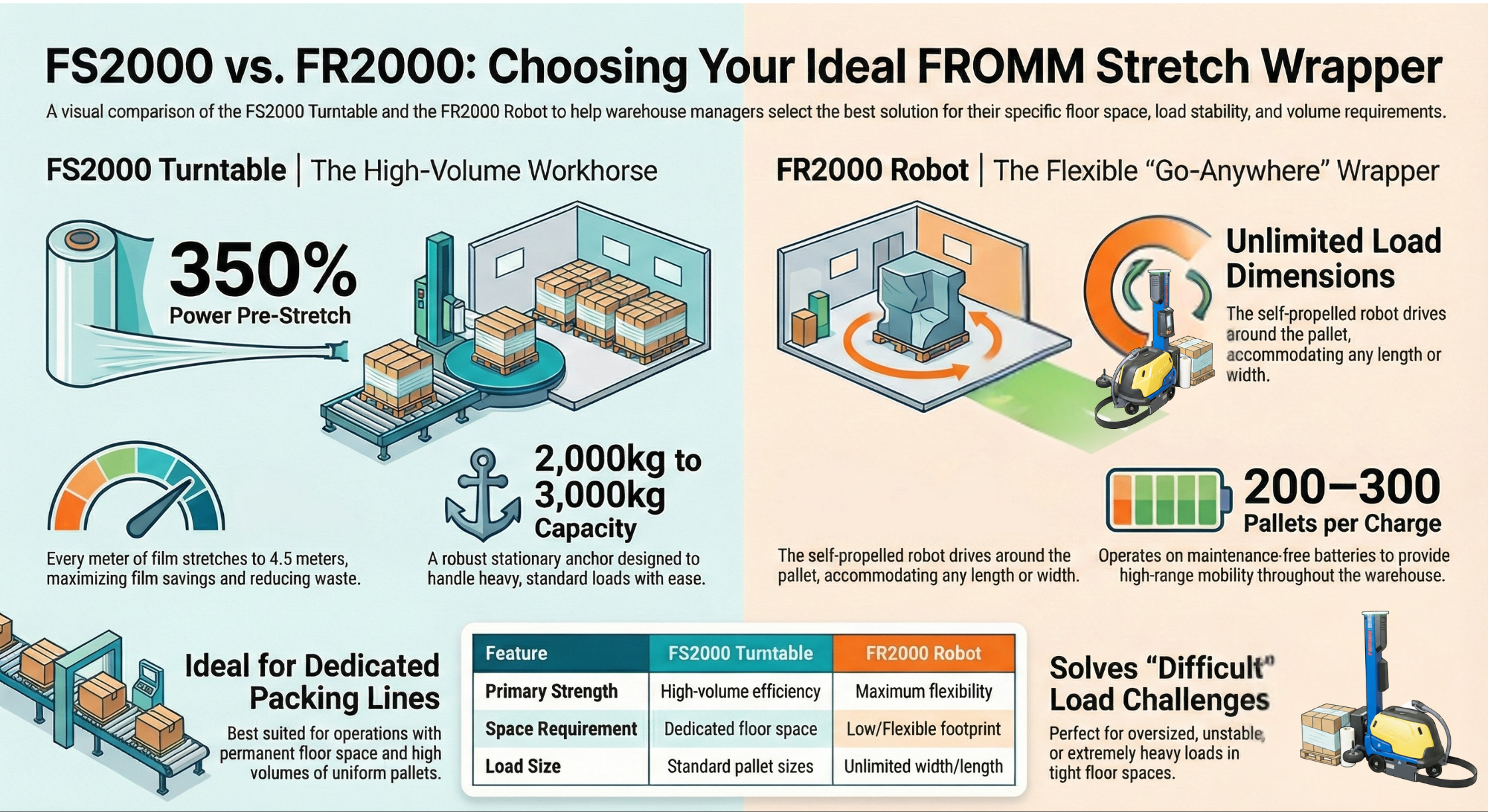

So let's talk about two heavy-hitters from FROMM's latest 2000 series: the FS2000 Turntable Wrapper and the FR2000 Self-Propelled Robot. Both leverage third-generation technology and the revolutionary Aeolus air-attachment system, but they solve fundamentally different warehouse challenges.

The FS2000: Your High-Volume Workhorse

Think of the FS2000 as the reliable anchor of your packing line. It stays put, wraps fast, and handles serious volume when you've got dedicated floor space for wrapping operations.

Where it shines

High-volume, uniform operations. You're running standard pallets through at consistent volume, and you've allocated permanent floor space to wrapping. This is your dedicated wrapping station for predictable loads.

The game-changer: 350% power pre-stretch This isn't just a spec—it's a sustainability and cost revolution. Every metre of film stretches to 4.5 metres. That's 72% less plastic waste, dramatic film cost savings, and a measurable step toward your ESG goals.

n an era where sustainability through automation is becoming mandatory (not optional), the FS2000's pre-stretch technology delivers both environmental and financial ROI.

Technical muscle

- Standard loads: Up to 2,000 kg (4,409 lbs)

- Heavy-duty upgrade: 3,000 kg (6,613 lbs) capacity available

- Turntable options: 1.5m to 2.6m diameter (5-8.5 feet)

- Mast heights: 2.45m standard, up to 3.9m available (8-12.9 feet)

- rapping speed: Frequency-controlled turntable, 5-12 RPM

Smart automation features

The state-of-the-art 7" touchscreen operating panel isn't just flashy tech—it's operational intelligence:

- 99 programmable wrapping cycles for different load types

- Multi-layer programming with precise film overlap control

- Film tension adjustment at every phase of the wrapping process

- Soft start/stop in zero position for consistent results

- Top and bottom wrapping cycles (1-10) for extra stability

The Aeolus advantage

Available as an option, FROMM's patented Aeolus air-attachment technology eliminates the need for manual film attachment. At the end of each wrapping cycle, the film is automatically cut and secured against the package using compressed air—no additional guards, no extra mechanisms.

The result? Remote operation capability, enhanced workplace safety, and labour savings that compound with every pallet wrapped.

The result? Remote operation capability, enhanced workplace safety, and labour savings that compound with every pallet wrapped.

The FR2000: The Go-Anywhere Wrapper

The FR2000 flips the script entirely. Instead of bringing pallets to the machine, this self-propelled robot drives to wherever your load is sitting. It's built for the awkward, oversized, and "how do we even wrap this?" situations that turntables can't handle.

Where it shines

Oversized, irregular, or super-heavy loads. When your pallets are too unstable, too large, or too heavy to safely spin on a turntable, the FR2000 is your solution. Also ideal when floor space is tight and you can't dedicate a permanent wrapping station.

Ultimate flexibility

Since the FR2000 wraps by driving around the stationary pallet, there's essentially no limit to load dimensions. Long lumber bundles, irregularly shaped machinery, fragile stacks—if it's on a pallet, the FR2000 can wrap it.

This is particularly valuable for operations handling diverse product mixes or custom orders where standardization isn't possible.

Serious operational range

Wrapping capacity: 200-300 pallets per charge (depending on pallet size and wrap cycles)

Maximum pallet heights:

- 2.15m standard (7 feet)

- Up to 3.5m available (11.5 feet)

Built for real-world conditions

The FR2000 is engineered for the chaos of actual warehouse environments:

- Ergonomic handlebar design for comfortable manual positioning

- Robust safety bumper for collision protection

- Visual and audible operational signals (green, red, blue status lights)

- Audio alerts at cycle start/stop

- Remote control operation for hands-free wrapping

Aeolus automation for mobile wrapping

The FR2000 with Aeolus technology represents the cutting edge of mobile wrapping automation. Position the robot against the pallet, start the cycle remotely (even from your forklift), and walk away. The system automatically:

- Wraps the complete pallet

- Cuts the film

- Secures the film end against the package using air

No manual intervention required. No additional safety guards needed. Just pure, efficient automation wherever you need it.

2026 Warehouse Trends: Why This Decision Matters More Than Ever

The choice between the FS2000 and FR2000 isn't happening in a vacuum. Three major industry shifts are reshaping how warehouses approach end-of-line automation:

1. Labour scarcity is accelerating automation adoption

With warehouse labour shortages at historic levels, every manual touchpoint becomes a bottleneck. Automated stretch wrapping addresses one of the most labour-intensive, repetitive tasks in the facility—freeing operators for higher-value work.

Modern solutions like the Aeolus system can handle 50+ pallets per hour with minimal human intervention, delivering measurable ROI through reduced labour costs and improved throughput.

2. Sustainability mandates are driving pre-stretch adoption

ESG goals are no longer optional. Automated systems with advanced pre-stretch technology (like both 2000 series machines) deliver:

- Energy-efficient operations with optimized routes and movements

- Precision film usage minimizing waste

- Measurable sustainability metrics for reporting

3. Flexibility is the new efficiency

2026 warehouse operations demand adaptability. AMRs and collaborative robotics are gaining traction precisely because they adjust to changing workflows without massive infrastructure investments.

The FR2000 embodies this trend: mobile automation that works in any location, with any load type, without permanent installation requirements. It's the stretch-wrapping equivalent of an AMR—flexible, scalable, and future-proof.

Making the Choice: FS2000 vs. FR2000

Choose the FS2000 Turntable Wrapper if you:

Choose the FR2000 Self-Propelled Robot if you:

- Run high-volume operations with consistent pallet sizes

- Have dedicated floor space for a permanent wrapping station

- Prioritize maximum throughput and wrapping speed

- Want the lowest cost per pallet wrapped

- Need industry-leading pre-stretch (350%) for film savings

- Operate in e-commerce, distribution, or manufacturing with standardized loads

- Handle oversized, irregular, or unstable loads

- Wrap pallets in multiple locations throughout your facility

- Have limited floor space for dedicated equipment

- Move super-heavy pallets (up to 2,000 kg) that shouldn't spin

- Need maximum flexibility for diverse product mixes

- Want mobile automation without infrastructure investment

Best for: High SKU operations, fulfillment centres, food and beverage distribution, pharmaceutical packaging Best for: Building materials, machinery manufacturing, custom fabrication, mixed-product warehouses, facilities with space constraints The Bottom Line

In 2026's automated warehouse landscape, stretch wrapping is no longer an afterthought—it's a strategic automation decision that impacts labour costs, sustainability metrics, throughput capacity, and operational flexibility.

Both the FS2000 and FR2000 represent FROMM's 75 years of Swiss engineering excellence applied to modern warehouse challenges. With third-generation technology, the revolutionary Aeolus air-attachment system, and industry-leading pre-stretch capabilities, either machine delivers measurable ROI.

The question isn't which is better—it's which solves your specific operational challenges.

High-volume, standardized operations? The FS2000 is your efficiency engine.

Diverse loads, tight spaces, maximum flexibility? The FR2000 is your mobile automation solution.

As warehouse automation continues its rapid evolution, one thing is certain: the facilities that invest intelligently in proven automation technologies today will dominate their markets tomorrow.

The 2000 series isn't just about wrapping pallets—it's about wrapping up your competitive advantage.