It’s a fact that today’s industrial manufacturing is leaner than ever before. Plant managers like you are constantly being asked to find ways to save time and cut costs.

If you feel like you’ve already looked at every avenue for improving efficiency, take a moment to consider your packaging processes. There may be solutions here that you haven’t considered.

Industrial packaging machines could help your plant save more time and money. Here’s how.

Industrial Packaging Systems Increase Throughput

Many manufacturers still use manual packaging processes. How many pallets can your team wrap per hour? How much strapping can they get done?

Even the fastest team can’t compare to automatic machines designed to wrap and strap pallets. Some of these machines have the capacity of up to 120 or 130 pallets per hour. What’s more, they don’t get tired like human workers do. They can hold that speed consistently throughout the day.

You can get more pallets wrapped, strapped, and shipped in less time. This increases your throughput, and it also reduces labour costs on the line.

It can also contribute to higher worker productivity. Employees who aren’t spending all their time packaging products for shipment can turn their attention to other tasks. Increased productivity is linked to higher production and higher revenue.

Keep an Eye on Storage Space and Inventory

Storage costs can quickly add up for manufacturers. If you’re not getting products packed up and shipped in a timely manner, it could be sitting around, taking up valuable space. Not only does this create clutter and potential hazards, it also costs money. You could be using that space for something else.

This is especially true in a warehouse. The more efficient the industrial packaging system you use, the more efficiently you’ll use storage space.

Industrial packaging systems can also help you keep an eye on inventory, especially packaging supplies. With better information about your supplies, you can manage inventory more effectively. This can help you keep just enough product on hand, without worrying about storing extra supplies or running out.

Improving Safety and Integrity

Another benefit of industrial packaging systems is their ability to improve safety in the plant. Their ability to free up your employees’ time was already mentioned, as was their consistent output.

Machines don’t get tired, unlike human workers. Your employees, on the other hand, will experience fatigue. This can lead to mistakes during packaging. In some cases, these mistakes can result in damage to the product during shipping. At other times, they could lead to employee injuries.

Either scenario has a higher cost for your business. An injured employee reduces productivity, and the injury could cost you in any number of ways. Damaged products could mean returns and claims, which have associated costs for your business. You also lose time processing returns and shipping out replacement products. The right system can help you reduce waste.

Industrial packaging systems improve the integrity of your packaging process and the safety of it as well. Finally, they can also help you keep the workplace uncluttered, which makes it safer for your employees.

The Right Training and Service

The right packaging system has other advantages for your plant. One might be improved maintenance and service offered by the solution supplier. This can help extend the lifetime of the machines and protect your investment in them. Good maintenance also reduces downtime, which saves time and reduces costs.

The right provider will be able to train your team to use the latest technology correctly. This helps your employees complete their tasks faster. It also extends the lives of the machines through correct use.

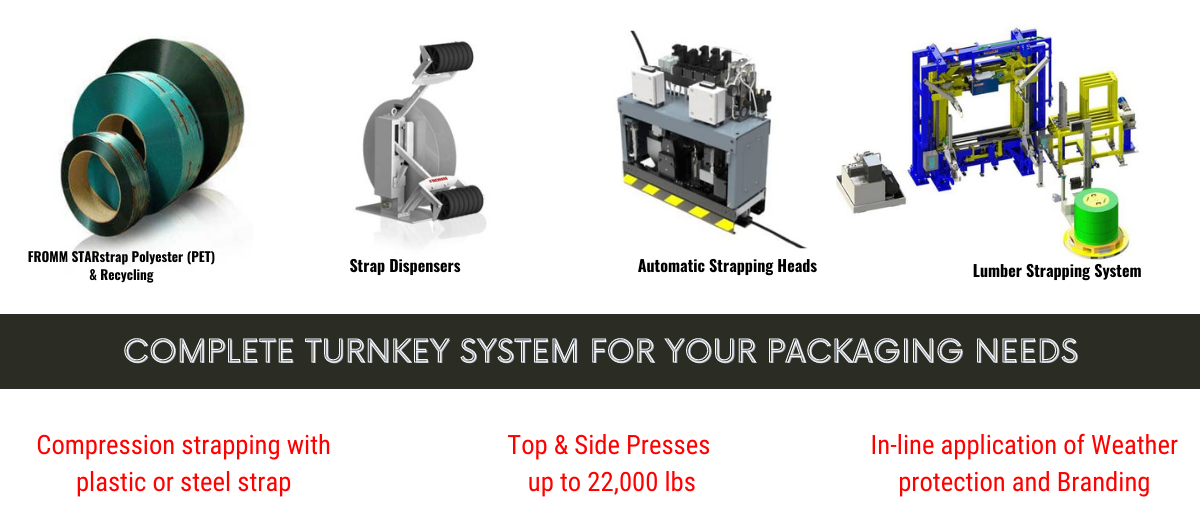

It’s clear industrial packaging systems have many benefits for your plant. Talk to a provider today and discover how you can build your own customized solution.