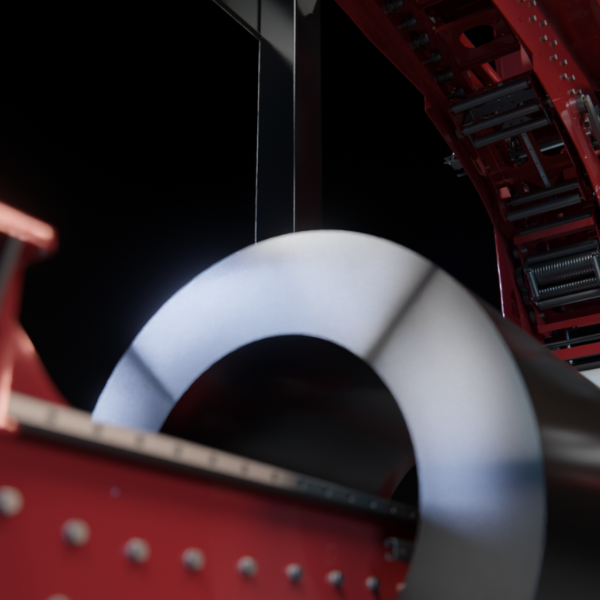

SILMA Coil Wrapping Machine

The SILMA coil wrapping machine is fully automatic and designed to eliminate manual handling, increase efficiency, and provide superior product protection for metal sheets and wire coils.

The SILMA coil wrapping machine is fully automatic and designed to eliminate manual handling, increase efficiency, and provide superior product protection for metal sheets and wire coils.

Welcome to the new era of Coil Wrapping

.png?width=500&height=500&name=Silma%20(1).png)

Fully Automatic, High-Speed Wrapping

SILMA coil wrapping machines offer fast, consistent wrapping, processing up to 45 coils per hour with minimal operator intervention.

100% Electric – No Compressed Air Required

These machines run entirely on electricity, ensuring higher reliability and lower maintenance costs.

Customizable for Various Coil Sizes

Versatile! The SILMA X1 and X2 accommodate a wide range of coil dimensions:

SILMA X1: Coil widths from 600 to 1,550 mm

SILMA X2: Coil widths from 600 to 2,300 mm

Both models support an inner core of 508 - 610 mm and an outer diameter of 800 - 2,200 mm.

Built for Durability & Efficiency

Powered by Siemens PLC & HMI, SEW motors, and integrated SEW inverters, these machines deliver superior energy efficiency, durability, and reliability, ensuring long-term ROI.

Ultimate Product Protection

Ensure your metal coils, wire spools, and cylindrical products are securely wrapped, dust-free, moisture-resistant, and ready for safe transport and storage.

20 rpm

Wrapping Speed 2.9s/ cycle

30-40%

Pre Stretch Film Carriage

45

coils/ hour

Whether you’re in steel processing, metal packaging, wire manufacturing, or the automotive industry, these machines streamline your operation and cut costs with cutting-edge automation. See it in Action !

The SILMA automate coil wrapping, handling up to 45 coils/hour. This dramatically reduces manual labor, speeds up production, minimizes errors, ensures consistent wraps, and frees up workers for more critical tasks.

Yes! SILMA X1 and X2 accommodate a wide range of coil widths, inner cores, and outer diameters, making them ideal for steel, aluminum, copper, wire, and other cylindrical products. With customizable settings, they seamlessly adapt to various industry needs.

Unlike pneumatic systems that require air compressors, hoses, and regular leak fixes, the SILMA coil wrappers are 100% electric, eliminating the need for compressed air. This reduces maintenance costs, prevents production downtime, and ensures greater reliability over time.